🤖 A Generalist Robot Brain

Good Morning, Roboticists!

Just as the West debates software architectures, China is wiring thought straight into machines—compressing the boundary between intention and action faster than anyone expected.

HUMANOIDS

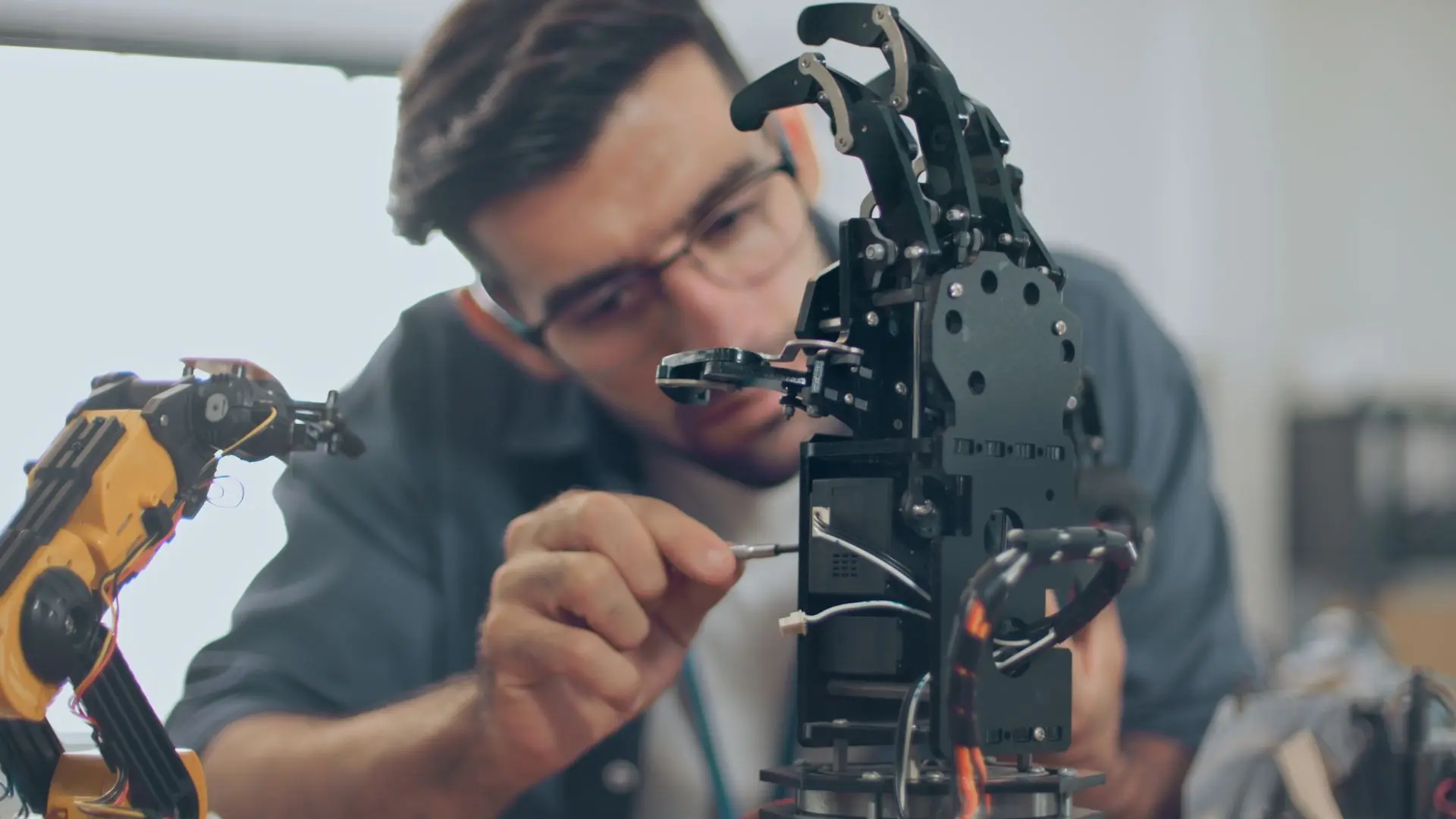

Boston Dynamics Bets Manufacturing On A Generalist Robot Brain

Boston Dynamics has shifted the conversation around Atlas. After a year of teasing hardware, the company revealed the software architecture behind its all electric humanoid. In a 40 minute technical discussion, Atlas VP Zack Jackowski and robot behavior lead Alberto Rodriguez laid out how they plan to build a generalist brain for factories. The tone mattered. Less parkour, more production. The claim is simple. Manufacturing is too chaotic for task specific robots, and humanoids are no longer a demo problem but a systems one.

The economic argument is the quiet center of this move. In a modern auto plant, one line can produce five models with thousands of part variants. Jackowski estimates a single hard automation cell costs over $1 million and takes a year to deploy. Multiply that by tens of thousands of tasks and the math breaks. You cannot automate a factory one machine at a time. A reprogrammable humanoid that adapts in days fits existing plants and avoids endless redesigns. That is the part many still miss.

If this works, factories stop buying machines and start buying capability. Software talent becomes the bottleneck, not steel. Hyundai’s role hints where this goes. Plants redesigned around generalists, fleets instead of pilots, and a slow collapse of rigid automation economics. The risk is execution. The direction is clear.

MANUFACTURE

PASCO Turns Palletizing Into Its Quiet Industrial Moat

PASCO just marked fifty years in industrial automation, and the story they chose to tell centers on one thing. Palletizing. It started in 1976 with a very specific problem at Monsanto. Manual drum lifting was injuring workers and slowing lines. Two engineers and a fabricator built a mechanical palletizer that actually worked. That moment stuck. Over decades, PASCO evolved that solution alongside the factory itself, moving from mechanical stackers to PLCs in the 1990s, then to FANUC robotics in 2004, and now to vision, AI optimization, and fully integrated end of line systems.

This matters because palletizing sits at the most underestimated choke point in manufacturing. It is the last step, but it dictates whether upstream gains survive. A slow palletizer can erase millions in efficiency. PASCO built its business around that reality. Today, robotic palletizers can handle dozens of SKUs, shift patterns on the fly, and integrate with warehouse and ERP systems. With labor shortages rising and throughput targets tightening, end of line automation is no longer optional. It is structural.

The bigger takeaway is strategic. PASCO did not chase novelty. They stayed anchored to a bottleneck that never went away. As factories move toward Industry 4.0, palletizing becomes a data node, not just a machine. If this trajectory holds, the companies that quietly own these unglamorous layers will shape how smart factories actually work.

NEW TECH

China Wired Human Intent Directly Into Working Robots

What just happened is not a brain-computer interface demo. Researchers at the Chinese Academy of Sciences put a fully implanted, wireless BCI into a paralysed patient and connected it to real robots. With thought alone, he controlled a cursor, did paid remote work, dispatched robotic dogs to fetch deliveries, and drove a smart wheelchair in daily life. This ran stably for weeks. Latency stayed under 100 milliseconds. That is below the body’s own neural delay. This feels different because the system left the lab and entered the physical world.

This matters because the real breakthrough is robotic control, not just brain sensing. The BCI is only the input layer. Value appears when human intent flows cleanly into machines that can move, navigate, and manipulate the world. That requires tight coordination across implants, wireless power, low latency communication, AI decoding, and robotic hardware. The system worked because every layer was designed to interoperate, from the chip in the skull to the robot on the ground.

If this continues, robots stop being tools and start becoming extensions. Training costs drop. Reaction speed improves. Human intent replaces joysticks, scripts, and voice commands. Medical use comes first. Industrial and defense systems follow quietly. The risk is not mind reading. It is who can turn thought into action at scale.

QUICK HITS

- Comau and X-Machine deployed an AI-driven robotic arc welding system for Tubosider to improve efficiency and reduce costs.

- UPS plans to invest about $120 million in unloading robots to cut costs, ease logistics bottlenecks, and support network restructuring.

- Aptiv and Vecna Robotics are partnering to build safer, lower-cost next-generation AMRs for warehouse and factory automation.

- Primech Holdings debuted Hytron at CES 2026 in North America, showcasing its AI-powered autonomous restroom cleaning robot.

- CMR Surgical’s Versius Plus received FDA 510(k) clearance and is set for U.S. market entry in 2026.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.