🤖 China Robots Dance Live

Good Morning, Roboticists!

The week opened with six humanoids dancing under arena lights.

HUMANOIDS

China’s Humanoid Robots Step Onto A Pop Star Stage

Six humanoid robots walked onto a live concert stage in Chengdu, China, and danced alongside China superstar Wang Leehom. They wore sequined outfits, moved in tight synchronization, hit musical cues, and ended the routine with simultaneous flips. This was not a tech demo or a closed event. It was a mainstream pop concert with thousands of spectators. The robots were supplied by Unitree Robotics. For the first time, humanoid robots were framed not as machines, but as backup dancers for a pop star.

This matters because pop culture is a credibility amplifier. Factories prove usefulness. Concerts prove acceptability. Dancing robots do not solve productivity problems, but they reshape public expectations fast. The jump from spinning props at a Spring Festival broadcast to coordinated flips in under a year shows how quickly capability and presentation are converging. Even Elon Musk shared the video on X, calling it impressive. That kind of signal turns a local performance into a global narrative.

If this trend continues, robot dancing will never stop being used as proof of progress. It is easy to film, easy to share, and easy to understand. The risk is distraction. Spectacle can mask harder questions about safety, cost, and real deployment. But directionally, it shows where humanoid builders are heading. Toward public spaces first, not factory floors.

MANUFACTURE

Chef Robotics Makes Food Automation Scale Feel Routine

Chef Robotics just released Chef+, its most advanced meal assembly robot so far. This is not a concept reveal. The system is already running in production, built on data from more than 80 million meals assembled in real factories. Compared with earlier models, Chef+ doubles ingredient capacity, keeps the footprint to roughly one worker’s space, and hardens the machine for cold, wet food environments. Alongside it, the company introduced a new pat down attachment that automates the previously manual step of flattening meals before sealing.

What makes this matter is how tightly it targets food manufacturing constraints. Floor space is fixed, labor is scarce, and food safety rules are unforgiving. Chef+ reduces refill interruptions, tolerates tray misalignment and speed changes, and simplifies cleaning by design. The vision system tracks trays continuously, while higher onboard compute adapts to variable ingredients in real time. The pat down capability closes a major gap by removing a repetitive human task that often limits throughput and creates downstream waste.

The impact is structural. With a RaaS model and $43 million in Series A funding, Chef Robotics Inc. is turning automation from a one off capital decision into an operating upgrade. If this deployment pattern continues, food factories scale output by software, attachments, and coordination, not by adding people or expanding buildings. That quietly resets how industrial food production grows.

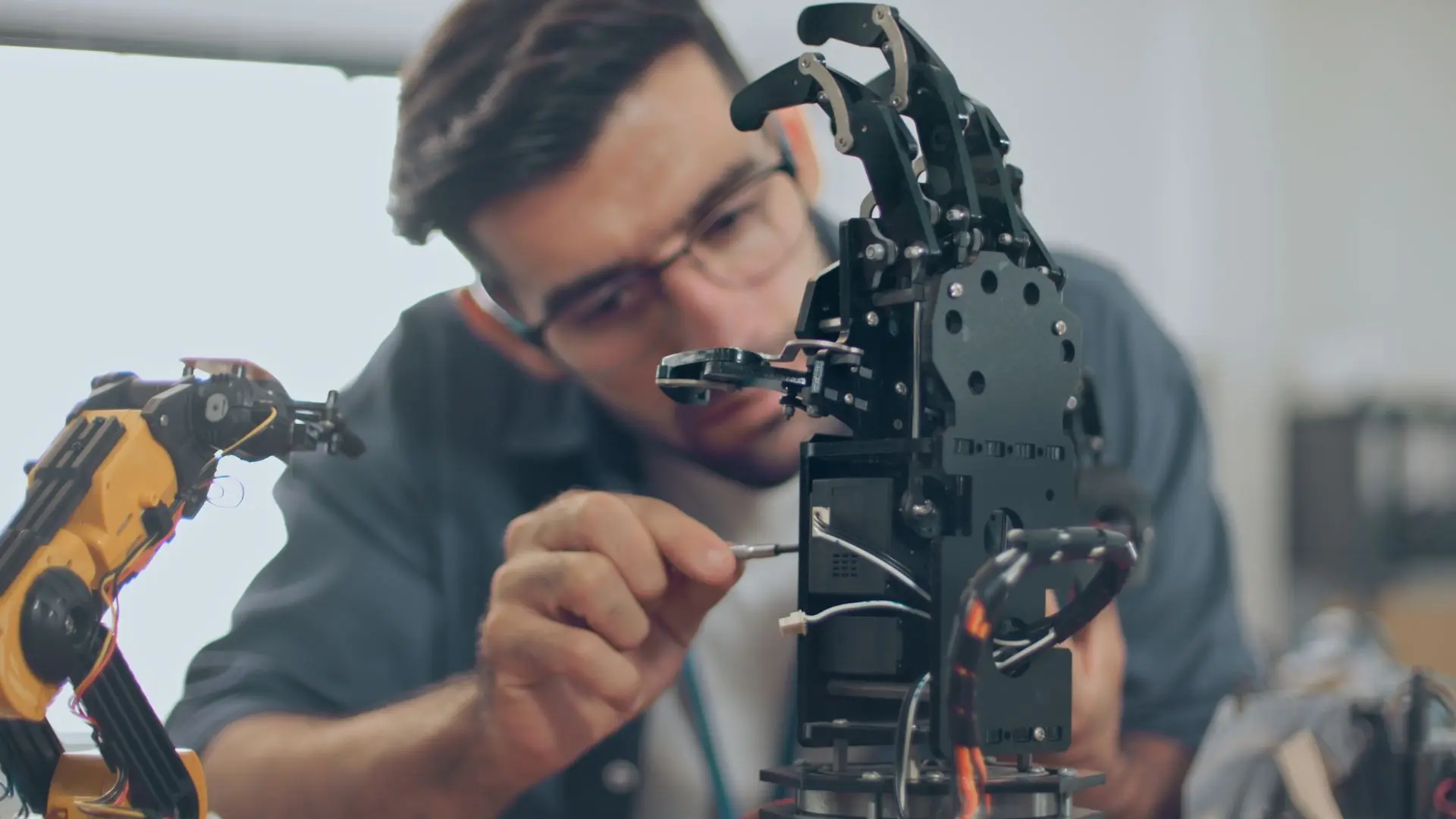

ROBOT HANDS

Dexterous Robotic Hands Move From Lab Scale to Industry

Sharpa Robotics has pushed its so called world’s most advanced SharpaWave robotic hand into mass production. This is not a prototype announcement. Manufacturing has shifted to a rolling process with automated testing that validates thousands of microscale gears, motors, and sensors inside every unit. Early shipments began in October, with scale up timed ahead of a CES 2026 debut. The hand is human sized, strength capable, and built with 22 active degrees of freedom. The important change is that Sharpa is treating dexterity as repeatable hardware, not a fragile research artifact.

This matters because the hand has been the bottleneck. Robots can move. They can see. They struggle to manipulate the human world. SharpaWave attacks that directly with over 1,000 tactile pixels per fingertip, vision plus touch sensing down to 0.005 newtons, and backdrivable joints rated for one million grip cycles. That combination reduces the need to redesign tools, fixtures, or environments. Hospitals, hotels, retail, and light industrial sites suddenly look reachable without custom infrastructure.

The implication is also a shift in where friction lives. When dexterous manipulation becomes reliable and manufacturable, deployment constraints shift away from hardware novelty. Open software, simulation compatibility, and endurance tested mechanics shorten the path from lab to field. General purpose robots start to look less experimental and more like infrastructure, with risk concentrating in training, safety certification, and supply chains rather than mechanics.

QUICK HITS

- Tesla showcased its Optimus humanoid robot in Berlin with a popcorn-serving demo, though its level of autonomy remains unclear.

- Otis has enabled robots to reliably use elevators by introducing cloud-based APIs that support scalable, two-way integration across commercial buildings.

- Grab is acquiring China’s Infermove to pull AI-robotics delivery tech in-house and accelerate its shift toward an automated, robot-driven logistics network.

- SenseTime enters embodied and spatial intelligence by open-sourcing Kairos 3.0 and launching robot dogs via Ace Robotics.

- Humanoid robot maker Galbot raised over $300 million at a $3 billion valuation to scale embodied AI robots.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.