🤖 Egg Kick

Good Morning, Roboticists!

As embodied AI moves from labs to live environments, every breakthrough arrives paired with a new vulnerability, forcing the industry to confront a harder question: are we scaling capability faster than control?

HUMANOIDS

Unitree Kicked Its Training Engineer’s Eggs

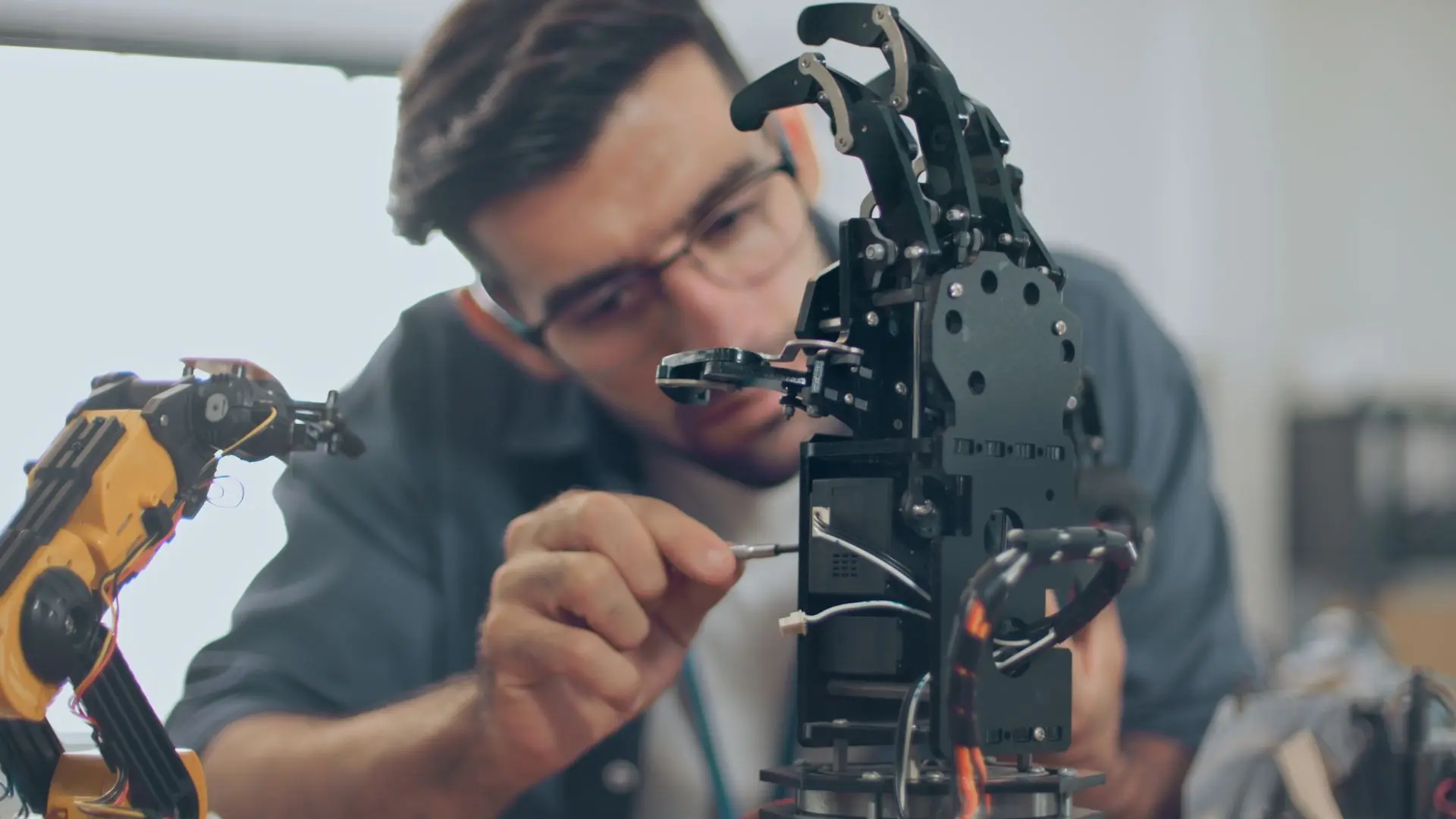

A short video from a Chinese robotics lab showed an engineer wearing a motion capture suit kicking during a humanoid training session. The robot, a G1 from Unitree, mirrored the motion exactly. Because both were facing the same direction, the kick had nowhere to go except back into the operator himself. The robot did nothing unexpected. It copied the movement with precision. The moment went viral because it looked silly, but it felt different from the usual robot fail clip.

What this exposed is not a control bug but a mindset gap. Motion capture systems like those from XSENS are built on literal mapping, not interpretation. The G1, priced around 21500 dollars and aimed at labs and industrial pilots, has no concept of demonstration versus execution. Engineers still rely on human intuition like knowing when a motion is symbolic or when force should be implied rather than applied. Robots do not share that assumption. They execute what they receive.

The direction this points to is clear. As humanoids become faster and stronger, intuitive training becomes unsafe. Robots need to be treated as machines, not partners. Training will shift toward constrained spaces, formal choreography, and fewer human bodies in close distance. The risk is not rebellion. It is precision applied without judgment.

HUMANOIDS

China’s Humanoid Robots Cross a Precision Work Threshold

A humanoid robot in China publicly stitched embroidery using both hands. It threaded a needle, managed tension, and completed a logo on soft fabric with sub millimeter precision. This was not a lab clip but a live demonstration. The robot came from TARS Robotics and showed stability throughout a task long considered off limits to machines. Until now, flexible materials and prolonged coordination were where automation quietly stopped.

The important shift is not embroidery itself. It is the class of work it represents. Tasks like wire harness assembly and delicate electronics still depend on trained human hands because small errors compound fast. TARS approached this by closing the loop between real world data, an embodied model called AWE 2.0, and physical robots designed to execute what the model learns without translation loss. That reduces the digital to physical gap that usually kills precision outside controlled settings.

This points toward automation expanding into places factories avoided. Generalized manipulation scales with data, not scripts. With more than $240 million raised in under a year, the TARS Robotics team is signaling sustained iteration. If this holds, soft material handling and precision assembly become the next testing ground for humanoid deployment.

HUMANOIDS

A Voice Command Broke the Safety Model For Robots

At GEEKCon in Shanghai, a security team showed how a $14,000 humanoid from Unitreerobot could be hijacked using spoken commands and short-range wireless links. After control was taken, it did not stay isolated. It passed the exploit to a second robot nearby that was offline and never connected to the internet. Within minutes both machines were fully controlled. To make the point concrete, the compromised robot was instructed to move forward and strike a mannequin on stage. The moment landed because nothing exotic was involved.

What this quietly breaks is the current safety logic around robots. Many teams assume that keeping machines offline or limiting them to local voice control reduces risk. The demonstration showed the opposite. Once one unit is compromised, proximity becomes the network. A single robot becomes a bridge. Other teams at GEEKCon highlighted similar weaknesses across smart devices and autonomous systems.

If this trajectory holds, robot security shifts from a software checklist to a fleet level problem. Voice interfaces, Bluetooth, and local autonomy stop being conveniences and start being liabilities. As companies like UBTECH push robots into public and industrial spaces, trust will lag capability unless security is designed as a physical systems discipline, not an afterthought.

QUICK HITS

- PollyPolymer adapted its 3D-printed footwear materials and fast manufacturing processes for humanoid robot components, expanding into robotics and global markets.

- Backed by the U.S. Army, Purdue University is developing air–ground AI robot teams for autonomous operation in GPS-denied environments.

- AgiBot launched Qingtian Rent, bringing humanoid robots into day-rate rentals and stress-testing Robots-as-a-Service at scale in China.

- The European Investment Bank is providing €50 million to Comau to support robotics and advanced manufacturing R&D.

- Norway’s No Isolation developed the AV1 telepresence robot to help sick children in the UK to attend classes remotely and stay socially connected.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.