🤖 First IP66 Humanoid

Good Morning, Roboticists!

From the first IP66-rated humanoid to a decisive joint actuator breakthrough and bin-picking systems finally scaling beyond demos, robotics is crossing a quiet but critical threshold.

HUMANOIDS

The First IP66 Protection Level Humanoid

DEEP Robotics says its DR02 humanoid has crossed a different kind of threshold. Not a new stunt or viral demo, but basic survivability. The company claims the robot now operates with IP66 protection, tolerates water and dust, and maintains balance during fast movements and external disturbance. Control updates focus on whole body coordination rather than isolated joints. The robot can recover from falls, stand up unaided, and move between actions without visible stalling. The framing is deliberate. This is positioned as a machine meant to leave the lab.

That framing stresses assumptions most humanoid programs still rely on. Many systems quietly expect dry floors, predictable forces, and short duty cycles. Once you add rain, debris, or repeated impacts, stability collapses. IP66 is routine in industrial equipment but rare in humanoids with 25 to 30 actuators. Maintaining balance while turning or kicking under disturbance pushes motion control, power delivery, and mechanical sealing at the same time. This is not about peak agility. It is about consistency across conditions.

If this trajectory holds, humanoids begin competing with rugged field robots rather than research prototypes. Logistics yards, inspection sites, and emergency response become realistic targets. The risk shifts to integration. Perception, compute reliability, and operational support must match the body. But the direction is clear. Deployment now matters more than spectacle.

NEW TECH

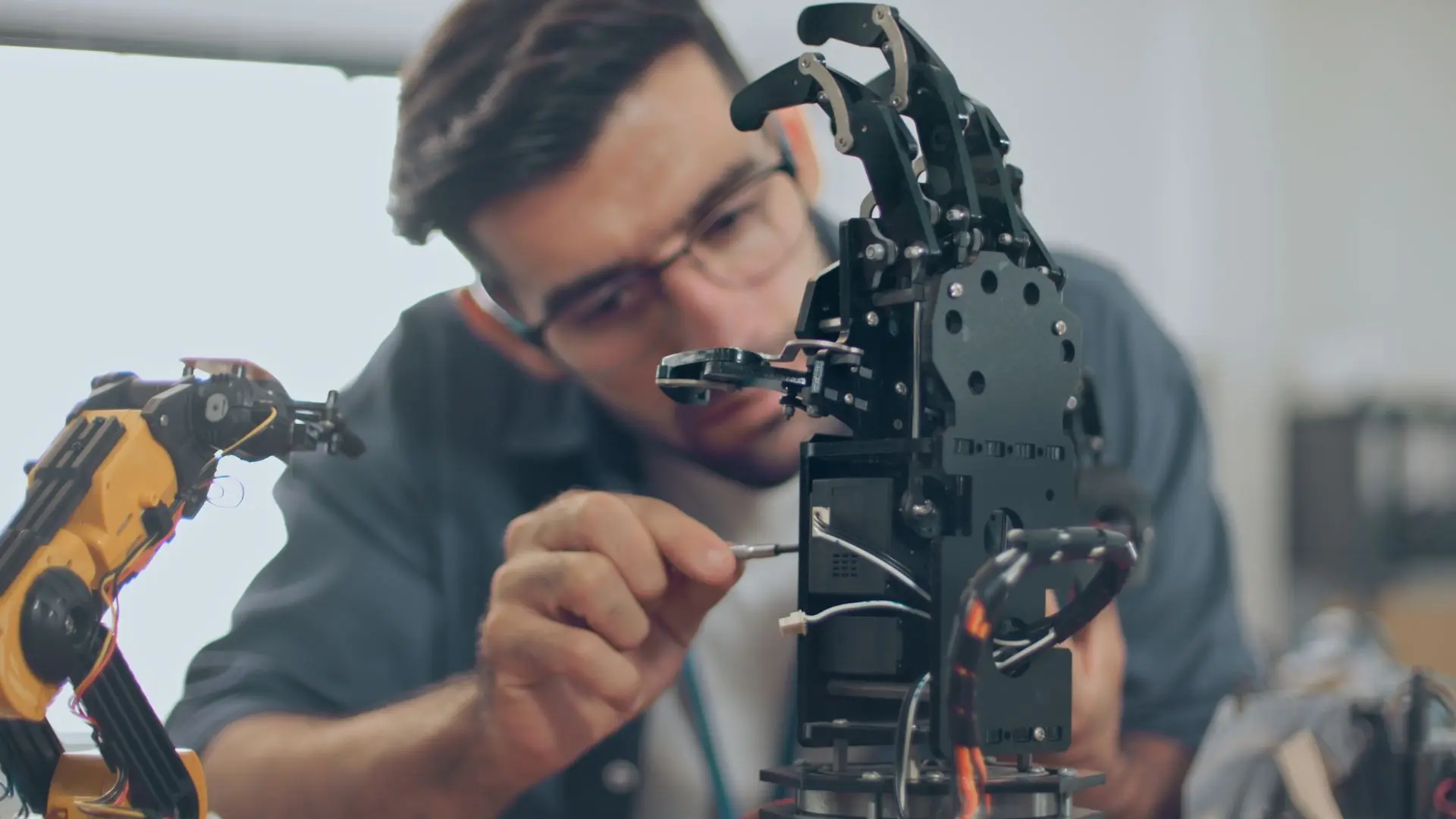

A Subtle Hardware Shift Inside Humanoid Robot Movement

Schaeffler has introduced a planetary gear actuator designed from the ground up for humanoid robots, not borrowed from automotive or industrial lines. Each humanoid needs roughly 25 to 30 actuators across hips, knees, shoulders, and arms. What changed here is not torque alone. It is controlled back drivability paired with precision. The actuator can be smoothly driven in reverse under external force without losing positional accuracy. All components are built in house and integrated into a compact unit meant for continuous duty, not lab demos.

This quietly breaks a long standing constraint in robot motion. Traditional actuators trade stiffness for safety or compliance for control. Back drivability is usually limited or avoided because it complicates stability. But humanoid robots operate in human spaces, where contact forces are constant and unpredictable. A joint that can yield, sense, and recover changes how balance, manipulation, and energy efficiency work together. At 60 to 250 Nm per joint, multiplied across a full body, this shifts the mechanical baseline most software stacks quietly assume.

If this holds up in volume, it draws a line between animated machines and physically capable robots. Motion stops being over constrained and starts behaving more like a system. That widens the design space for walking, lifting, and human interaction. The next gains may come less from models and more from joints that finally behave like they belong in the world.

MANUFACTURE

Robots Stop Guessing Where Parts Are

At the end of December, Inbolt launched a new bin picking system on the robot arm that departs from how factories usually solve the problem. Instead of fixed overhead cameras and precomputed grasp points, a 3D camera sits directly on the robot arm. Vision moves with the hand. The robot observes parts while approaching, adjusts during grasping, and keeps correcting while placing. It works in bins where parts are random, shifting, or partially hidden. This is not just a lab demo. It is already running in multiple factories.

Bin picking has been one of automation’s most stubborn friction points. Traditional setups are expensive, brittle, and slow to reconfigure. Most plants tolerate them because alternatives rarely survive real production. Inbolt reports cycle times under one second and success rates up to 95 percent, using one camera per robot instead of per bin. That cuts hardware cost, simplifies integration, and reduces downtime during changeovers. The system accepts imperfect grasps and corrects continuously, rather than betting everything on a perfect initial plan.

The deeper signal is architectural. Intelligence is moving closer to the actuator, not sitting above it. Running on Nvidia hardware, this approach favors fast feedback over heavy models. If it scales, factories gain robots that redeploy easily across tasks. Flexibility starts to matter as much as throughput, especially in mixed production lines.

QUICK HITS

- Industry voices now warn that humanoid robots are overhyped, expensive, and still far from being genuinely useful products despite bold promises.

- Physical Intelligence’s “Robot Olympics” tests the π0.6 generalist robot on real household tasks, revealing its strengths and limits.

- Cyngn partnered with Chandler Automation to bring its autonomous DriveMod Tugger into agriculture and food processing operations.

- Kardome positions spatial, edge-based hearing as a core capability for human-like interaction in physical AI systems.

- China is reshaping robot and AI behavior with over 24 rules, emphasizing state oversight beyond Asimov’s three laws.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.