🤖 Lunar Cave Robots

Good Morning, Roboticists!

Robotics is crossing from controlled environments into messy, physical reality, setting the stage for what 2026 will demand.

LUNAR

KAIST Chooses Simpler Hardware for Lunar Cave Exploration

A South Korean team has tested a compact lunar rover built to survive caves, not open plains. Engineers at KAIST designed wheels made from woven metal strips that expand and contract, letting the robot roll over rocks, squeeze through narrow gaps, and absorb hard drops. In recent trials, the rover cleared 200 millimeter obstacles and withstood impacts meant to simulate being dropped deep into lunar pits. The results were published in Science Robotics, but the shift is bigger than the paper.

Most cave concepts lean on complexity. Past teams paired rovers with drones, betting on aerial scouts to handle blind corners and vertical shafts. KAIST is taking the opposite path. No flying hardware. No coordinated swarms. Just wheels that grow from roughly 9 to nearly 20 inches, spreading weight, improving traction in dust, and acting as built in shock absorbers. Fewer moving systems. Fewer failure modes.

If this approach scales, lunar cave missions look more industrial than experimental. A carrier rover drops simple explorers and lets physics do the work. The direction favors robustness over elegance. The risk shifts to autonomy underground, navigation without GPS, and power endurance. But the design logic is clear. Reduce assumptions. Let mechanics shoulder uncertainty.

HUMANOIDS

Soft Objects Stopped Blocking Humanoid Robots Sooner Than Expected

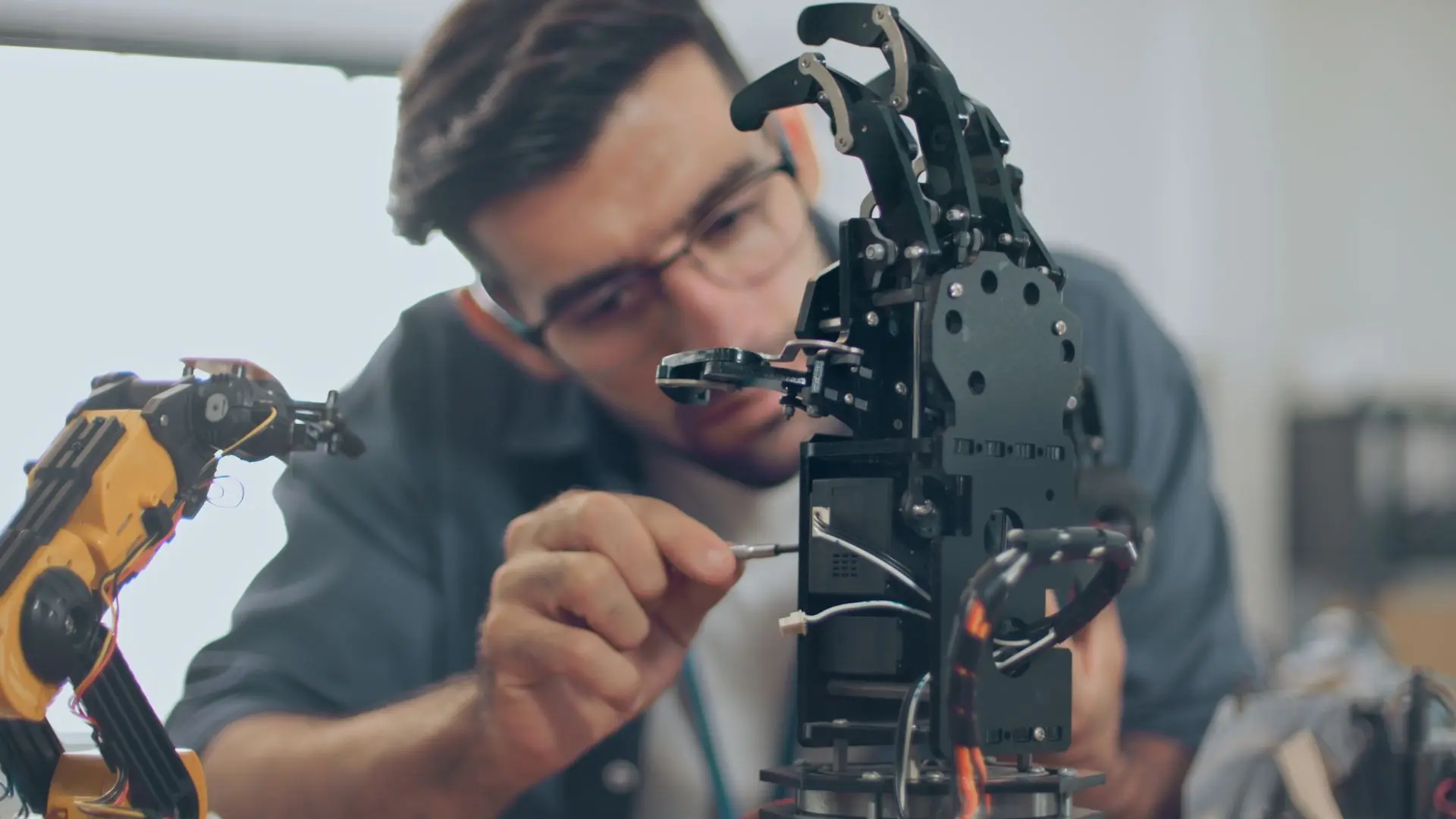

A small US robotics startup called Kinsi Robotics released a video that looks almost trivial. Its KR-1 muscular humanoid watches a human fold a towel, then does it on its own. The towel starts in random positions. The folds are not scripted. The robot adapts as the fabric shifts. This feels different because soft objects like cloth have long been treated as the line robots cannot cross without massive engineering effort.

Until now, handling deformable objects has mostly been tackled by large scale systems. Companies like Figure AI or Tesla rely on deep sensor stacks, heavy simulation, and long training pipelines to make progress on similar tasks. Those approaches work, but they assume capital, time, and controlled environments. Kinsi took another route. Through kinesthetic teaching, a human physically guides the robot while it records vision and motion together. The system learns a direct mapping from what it sees to how it should move, without labeling edges or modeling cloth physics.

The implication is not that this beats large engineering platforms. It suggests something more subtle. Soft objects may no longer be a fundamental barrier. With demonstration driven learning, they become a data and iteration problem. That lowers the entry cost for useful humanoid skills and shifts the bottleneck away from hardware scale toward learning speed and deployment context.

TREND

Robots Cross the Line From Tools to Co-Workers in 2026

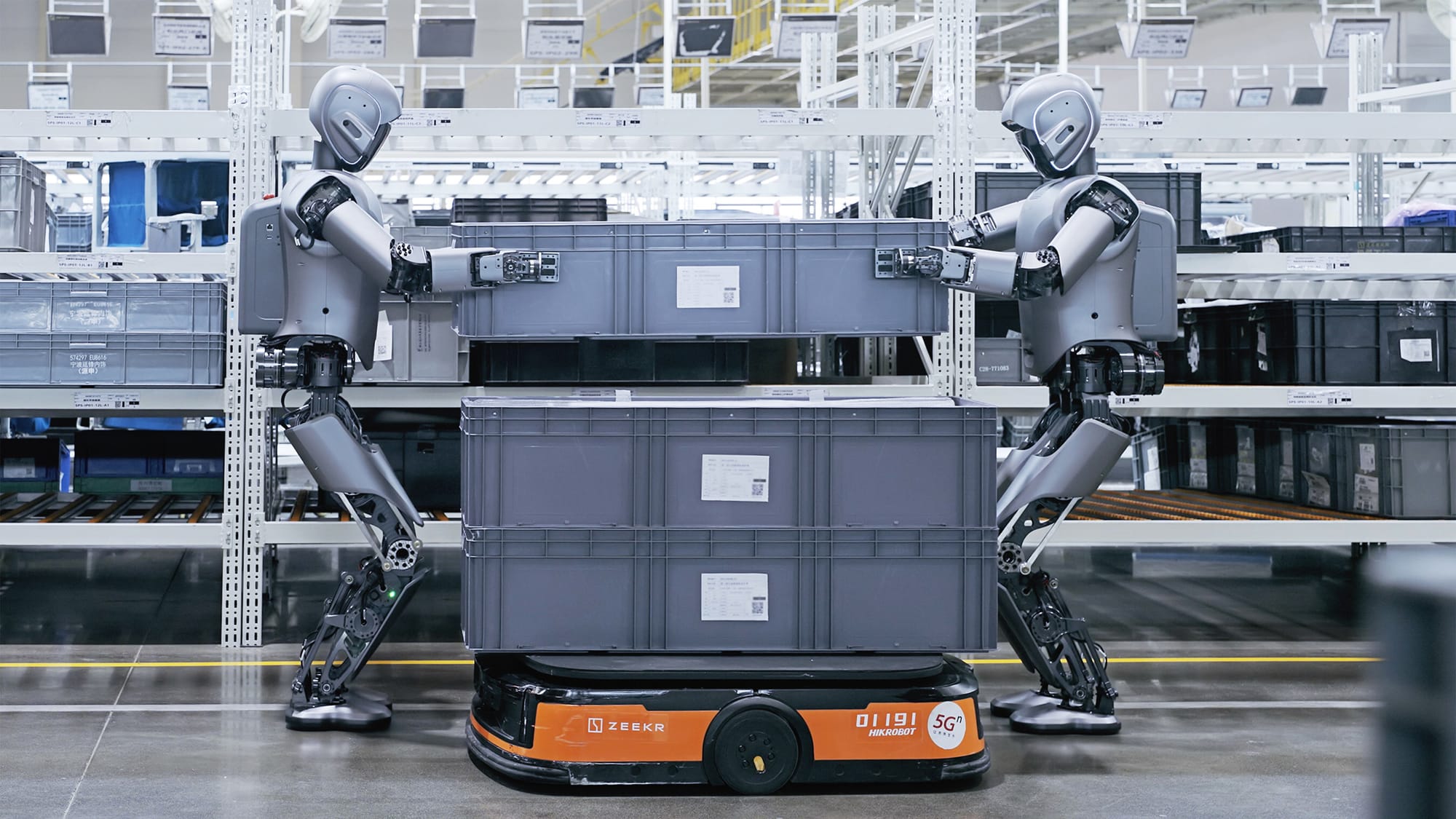

Deloitte frames 2026 as the moment robots stop behaving like rigid automation and start operating as adaptive physical systems. These machines no longer rely on fixed scripts. They perceive environments, reason about change, and adjust actions in real time. Training happens first in simulation, then transfers into the physical world with fewer surprises. As a result, robots are moving out of cages and labs and into warehouses, factories, hospitals, and energy sites where conditions are messy and unpredictable.

This shift quietly unsettles long-standing assumptions. Robotics programs were designed around isolation, repeatability, and deterministic safety rules. Physical AI breaks that model. Deloitte points to large scale deployments where robots are managed as fleets, continuously learning from live data. At that scale, the challenge is no longer whether a robot can perform a task, but whether systems can maintain reliability, safety, and human confidence when thousands of machines make real time decisions.

Looking ahead, Deloitte expects enterprise settings to remain the proving ground in 2026. Warehousing, manufacturing, health care, and infrastructure lead due to labor pressure and safety exposure. Humanoid robots sit further out, valued less for efficiency than for compatibility with human spaces. Progress is steady, not explosive. Robots become part of operational infrastructure, and risk concentrates wherever adaptive machines share space with people.

QUICK HITS

- Zerith Robotics is mass-producing and deploying its low-cost H1 service humanoid, accelerating commercial rollout.

- Malaysian indigenous primary school students won gold at the International Robot Olympiad with a Mars exploration robot concept.

- Oversonic Robotics and STMicroelectronics signed a deal to deploy RoBee humanoid robots in semiconductor fabs.

- Physical Intelligence showed that fine-tuned π0.6 can handle “Robot Olympics” tasks, highlighting pre-training gains while hardware remains a bottleneck.

- UK startup ScrubMarine raised €849k to speed up autonomous robots replacing risky subsea operations.

TOGETHER WITH US

AI Secret Media Group is the world’s #1 AI & Tech Newsletter Group, reaching over 2 million leaders across the global innovation ecosystem, from OpenAI, Anthropic, Google, and Microsoft to top AI labs, VCs, and fast-growing startups.

We operate the industry’s most influential portfolio of newsletters, each shaping a different frontier of the AI & Tech revolution:

Be Smarter in 5 Minutes

- AI: AI Secret

- Tech & Business: Bay Area Letters

- Marketing: Marketing Secret

Discover the Future Products

- AI Launchpad: Oncely

- Robotics: Robotics Herald

- Hardwares: The Hardwire

We've helped promote over 500 Tech Brands. Will yours be the next?

Email our co-founder Mark directly at mark@aisecret.us if the button fails.